| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | MZZG |

| Supply Ability : | 10 set 15 set per month |

| Price : | Negotiation |

| Delivery Time : | 35 work days |

| Payment Terms : | L/C, T/T |

| Model Number : | MZ18-100 |

Customized Tailing Recycling Machine Advanced Technology With 4

Water Cyclones

Product display:

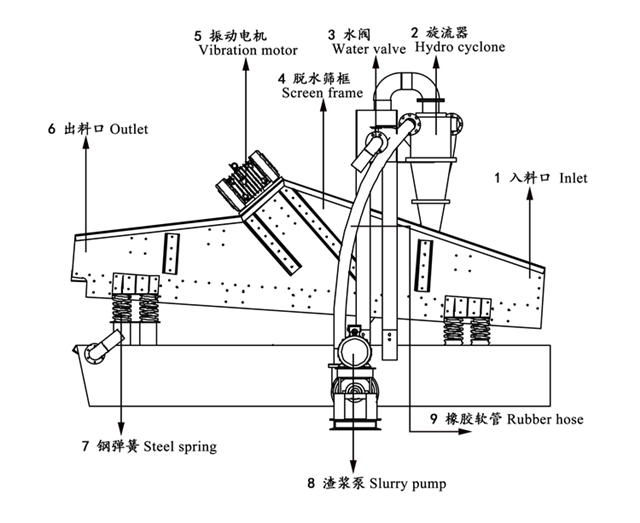

Working principle:

The finished material of the sand washing machine directly enters

the dewatering screen for dehydration. The mud water discharged

from the sand washing machine enters the equipment cleaning tank,

and is pumped to the high pressure separator through the bottom

vacuum high pressure pump for classification and concentration. The

sand mouth enters the dehydration, and other waste water, mud,

powder, impurities, etc. are discharged into the return water tank

through the overflow port of the high pressure separator.

Tech specification:

| Model | Water Consumption (m³/h) | Screen size W*L(mm) | Cyclone Model /NO.(mm) | Power (Kw) | Weight (kg) | Dimension L*W*H(mm) |

| MZ09-25 | 30-60 | 900*1800 | 250 | 12.5 | 1400 | 2000*1300*2900 |

| MZ12-30 | 50-120 | 1200*2400 | 300 | 19.5 | 2044 | 2515*1580*2930 |

| MZ15-65 | 80-160 | 1500*3000 | 300/2 | 36 | 3000 | 3327*1880*3200 |

| MZ18-100 | 150-240 | 1800*4500 | 250/4 | 52 | 7164 | 4744*2500*3200 |

| MZ24-120 | 200-300 | 2400*4500 | 300/4 | 75 | 8200 | 4744*3200*3200 |

| MZ24-180 | 300-400 | 2400*4500 | 300/6 | 89 | 8800 | 4744*3200*3200 |

Application :

Widely used in mud purification, artificial sand production line, hydro power station and sand aggregate system, glass raw material processing system and coarse slime recovery, and fine material recovery.

Main points:

1. It can effectively reduce the runoff amount of the fine

material; solve the problem of end product fineness modulus on the

high side, stone powder content on the low side.

2. The fine material can be recycled as high as 95%, with

incomparable technical and economic advantages

3. The machine will be assembly by our factory before complete

supply; users shall inspect the machine carefully after receiving

it, in order to avoid the contingent collision damage during the

process of transportation.

4. The installer should be familiar with the product structure,

performance and technical requirements, formulate appropriate

procedure in advance of the installation.

Structure:

Features:

1. Vertically install the cyclone for higher recovery

2. The underflow of the cyclone is stable and the dehydration

efficiency is better.

3. Easy to connect sand washing machine, saving land.

Widely used in mud purification, artificial sand production line, hydro power station and sand aggregate system, glass raw material processing system and coarse slime recovery, and fine material recovery.

I need to ask you some details for sending you the more suitable quotation.

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

|